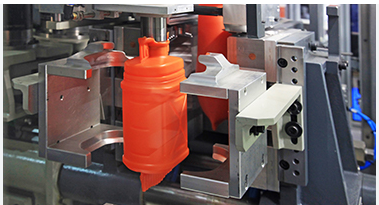

Rotomolding can be a very much utilized manufacturing process because it is quite inexpensive. Its principal goal is always to Plastics Rotomolding design polymers, altering them into thermoplastics. The most used polymers are Pvc material, polyethylene, and polypropylene in this sort of exercise.

A variety of companies can produce through the most basic to very complicated supplies throughout the rotational molding procedure. Also, dependant upon the intent behind the plastic material substance, it is actually a more common choice than possibilities such as coming, injections, and vacuum procedure.

Rotational Molding is a procedure that allows the creation of straightforward materials as well as a higher level of complexness. These sections are hollow and air-tight, modest, just like a coin, or large, like 25,000-liter tanks.

In this particular bit, the residual challenges are typically small due to the absence of tension in the resin. This process also handles the creation of inserts, threaded parts, gussets, increase wall space, pockets, and openings enabling components and colours being easily replaced.

A totally controlled procedure

To achieve good quality elements using a very well-managed method, you must have professionals. Granger Plastic materials Organization is the ideal partner for companies that want the very best plastic materials merchandise.

The tools and molds utilized in Plastics Rotomolding are generally cheaper than other molding functions. This is determined by reduced-charge resources such as nickel, light weight aluminum, or steel. In addition, the pieces produced by them do not need sizeable closing concluding operations.

One of the greatest features of this particular processing is the fact that rotomolding polyethylene can result in more robust pieces with a decent shelf-life. Regardless of how a lot this uncooked materials is commonly used by around 90% in the rotational molding market place on earth.

A completely personalized support

Hardly any businesses around the world provide the Rotational Molding support provided by Granger Plastics Organization because it offers the last finishing service after Molding, storage of pieces, and dispatching these to finish buyers.

Furthermore, in the event you have to have the design and style and manufacture of molds, there is a specialised unit that gives you total services. They ensure that this molds are fully functional and produce the items using the required requirements.